Predictive maintenance, also known as condition-based maintenance, has gained increasing attention with the rise of IoT and AI-driven smart factories. But what exactly is predictive maintenance? Where did it originate, and how is it evolving? Let’s take a closer look.

What is Predictive Maintenance?

Predictive Maintenance (PdM) is a data-driven approach to equipment maintenance. By using sensors and collecting data such as vibration, temperature, sound, and electrical current, it continuously monitors the health of machines in real time and predicts when a failure might occur. It can be compared to a health check-up for the human body—detecting early warning signs and taking preventive action before a major issue arises.

Difference Between Predictive Maintenance and Traditional Maintenance

First of all, if we look at the evolution of equipment support concepts, it can be roughly divided into three stages

1.Corrective MaintenanceCorrective Maintenance, as the name suggests, refers to repairing equipment only after it has failed. On the surface, this approach may seem to offer the lowest maintenance cost since no resources are spent in advance. However, when a failure occurs, the resulting losses often far exceed the repair expenses. These may include production line downtime, product scrap, and even delivery delays. For operators, the real burden lies not in the repair cost, but in the unexpected downtime and loss of production capacity—risks that can severely impact business operations. |

.png) |

|

2、Preventive Maintenance(PM) The traditional "repair before damage" strategy (also known as "planned maintenance" or "periodic maintenance") usually sets a fixed number of uses or time intervals for regular replacement and maintenance based on past experience. However, this approach often fails to reflect the changes in environmental conditions in actual operation or the impact of performance differences between components. The results may be two extremes: one is that even if the scheduled maintenance is performed, unexpected equipment failures still occur; the other is that the equipment can continue to operate, but it is replaced prematurely due to excessive concerns, resulting in unnecessary waste of resources and increased costs. |

.png) |

3.Predictive MaintenancePredictive maintenance is also known as condition monitoring, and its core concept is "if there is no abnormality in the equipment, there is no need for maintenance." Through the continuous collection of vibration, temperature and other data by front-end sensors, and combined with analysis software for diagnosis and prediction, we can grasp the time point and abnormal location of potential equipment failures in advance, and arrange maintenance work at the best time without affecting production, so as to achieve a maintenance strategy with minimum interference and maximum benefits. |

.png) |

This shows that predictive maintenance can bring benefits

|

|

|

Knowing the timing of equipment failure:Avoids unnecessary maintenance that leads to wasted resources and unplanned downtime. |

Schedule maintenance at the optimal timeKnowing the expected failure timing allows for efficient coordination of maintenance personnel and the delivery of necessary spare parts. |

Prevent unexpected breakdowns and downtime |

|

|

|

Improve production efficiency |

Identify the exact point of failure |

Enhance safety |

Common Tools and Technologies for Predictive Maintenance

|

|

|

|

Vibration Monitoring |

Infrared Thermography |

Ultrasound / Acoustic Emission |

Oil Analysis |

Among these, vibration monitoring stands out as the most widely used and mainstream tool and technique in predictive maintenance.

It is especially effective for detecting early signs of mechanical issues such as unbalance, misalignment, bearing wear, and looseness—making it a core method for monitoring rotating machinery like motors, pumps, and fans.

Predictive Maintenance Today's Development

1. IIOT trend, the rise of MEMS sensors:With the accelerated development of the Industrial Internet of Things (IIoT), MEMS sensors have rapidly emerged due to their small size, high integration and reduced costs, becoming the core components of smart monitoring.

|

|

|

2. Smart factory big data application:Integrate equipment monitoring data into IT systems and transform them into decision-making analysis basis, promoting the transition from on-site operation and maintenance to high-level operation optimization. |

3. Introduction of AI technology:Through the intervention of AI algorithms, the analysis, diagnosis and decision-making process of equipment abnormalities are made more automated and accurate, greatly reducing the burden of manual judgment. |

|

|

4. Wireless solutions are becoming more mature:With the rapid maturity of wireless communication technology and the improvement of the stability of the application environment, coupled with the continuous increase in on-site wiring construction costs and labor costs, wireless solutions have gradually become the mainstream choice for the deployment of predictive maintenance systems, especially suitable for the rapid introduction of existing factories and large equipment. |

As can be seen, as production systems become increasingly complex, the losses caused by sudden downtime are becoming more serious, and with rising labor costs, traditional manual inspections are no longer able to meet demand. As sensor costs drop significantly, wireless communication technology matures, and ESG and energy efficiency issues are receiving attention, companies need a more stable and long-term equipment operation mechanism. These factors jointly promote predictive maintenance (PdM) to become a core strategy in smart factories.

|

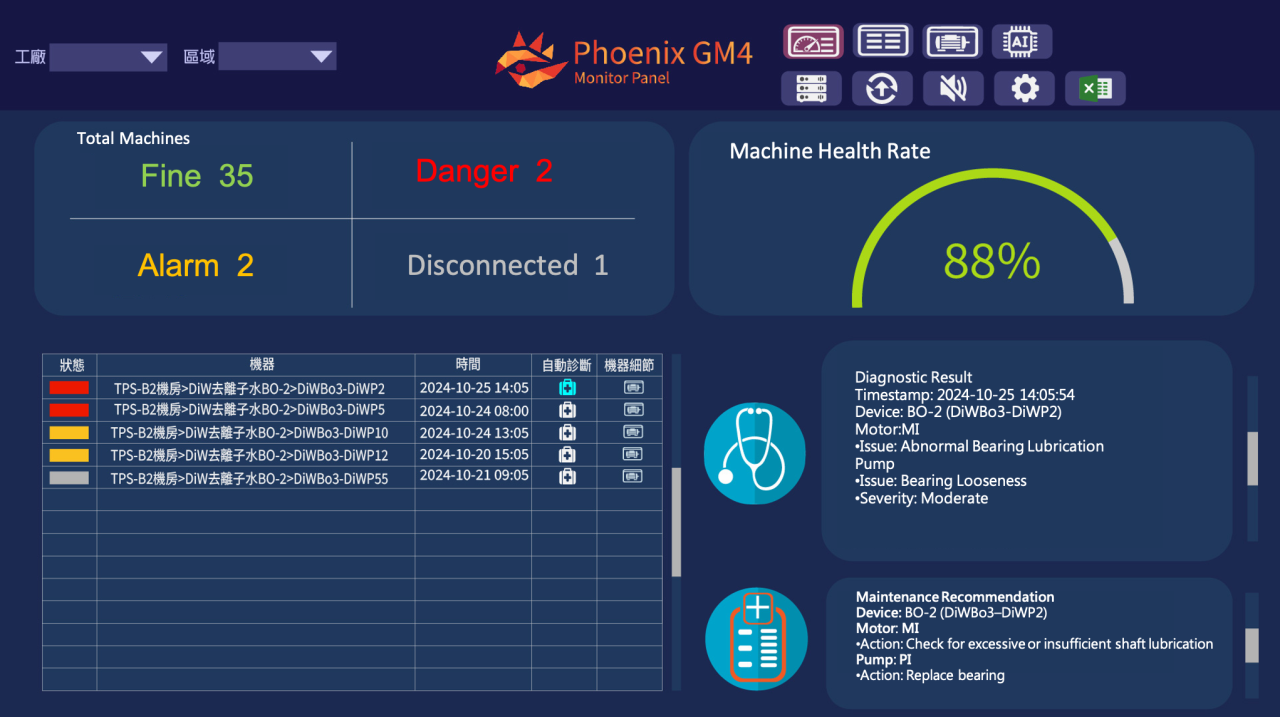

Predictive Maintenance and PROWAEVE

Since its establishment, PUWEI Technology has been deeply engaged in equipment predictive maintenance for more than 30 years. It has independently developed the GM4 smart diagnostic platform and wireless sensors, accumulated a large amount of field failure data and abnormal cases, and created a solution suitable for today's factories, which is practical, innovative, and cost-effective. GM4 provides vibration spectrum, automatic diagnosis, trend analysis and reporting functions, and continuously optimizes system performance through actual customer feedback, helping enterprises to discover equipment risks in advance and achieve stable and efficient smart maintenance management.

1.Complete solution

We can provide the most comprehensive predictive maintenance system options, from the most basic vibration meter to online monitoring and diagnosis systems, according to the different needs, restrictions and budgets of customers.

2.Transmission method

We can provide wired, wireless, manual inspection and other solutions according to different environmental restrictions on site.

3. Leading the trend, comprehensive functionsPROWAVE's predictive maintenance solution is at the forefront of the trend of smart maintenance, integrating core functions such as automatic diagnosis, AI prediction, and real-time alarm to help customers grasp the health status of equipment in advance and reduce the risk of downtime. We continue to listen to user needs and create a complete and flexible platform, from on-site sensing to cloud analysis, to fully meet the various application needs of enterprises in the transformation of smart factories. |

|

4. Equipment Diagnosis Service

PROWAVE is different from general maintenance manufacturers. We not only provide systems, but also understand the various problems encountered during on-site installation and have rich problem-solving capabilities and experience. In addition, our equipment diagnosis team can work with equipment repairers to provide the most complete predictive maintenance service.

Prowave entered the field of equipment monitoring over two decades ago, recognizing early on the challenges of relying on imported solutions—such as high costs, maintenance difficulties, and limited adaptability to local operational needs. In response, we made the bold decision to develop our own predictive maintenance systems tailored to the realities of the field.

Through twenty years of hands-on experience and continuous customer feedback, our 『Phoenix series』 has grown into a robust and mature product line, now widely adopted across industries such as petrochemicals, electronics, textiles, and manufacturing—earning strong recognition and trust from the market.

As one of the few Taiwanese brands with in-house sensor and diagnostic platform development, 『Prowave 』 stands as a trusted leader in Taiwan’s smart maintenance sector. With a vision of 『"From Taiwan to the World,"』 we are committed to driving local innovation onto the global stage—demonstrating the power and potential of Taiwan’s R&D excellence.