Cooling towers are important cooling equipment for many oil refineries, semiconductor factories, electronics factories, power plants, natural gas processing plants, petrochemical plants, hospitals and other industries. Heat exchange, so that the waste heat is transferred to the air and dispersed into the atmosphere to cool the large amount of waste heat generated by the operation of the plant.

Cooling tower failures can have serious consequences for plant business operations, such as failure of other equipment, safety of personnel, lost revenue from downtime, costly repairs and health issues. Common causes of cooling tower failure are usually related to misalignment or imbalance of the mechanism. Research shows that the most common failures in cooling tower structures are related to drive motors (60%), gearboxes (30%), fans (2%) and others (8%). More specifically, motor failures can be caused by unbalance, shaft misalignment, rotor defects, damaged bearings, and loose bases. Common causes of gearbox failure include stress in the cooling tower airflow, misalignment of the gears to the motor, increased stress between the gears and bearing failure. Fan failures can be caused by unbalanced fan blades, variations in blade pitch, or errors.

Vibration and temperature monitoring can effectively prevent sudden damage. The most important measures to be taken are to measure the vibration data of the cooling tower through the measurement of key vibration parameters and frequency spectrum analysis.

In general, most cooling tower fans run between 90 and 300 revolutions per minute (rpm), while motors used in cooling towers typically run at around 1,500 to 1,800 rpm.

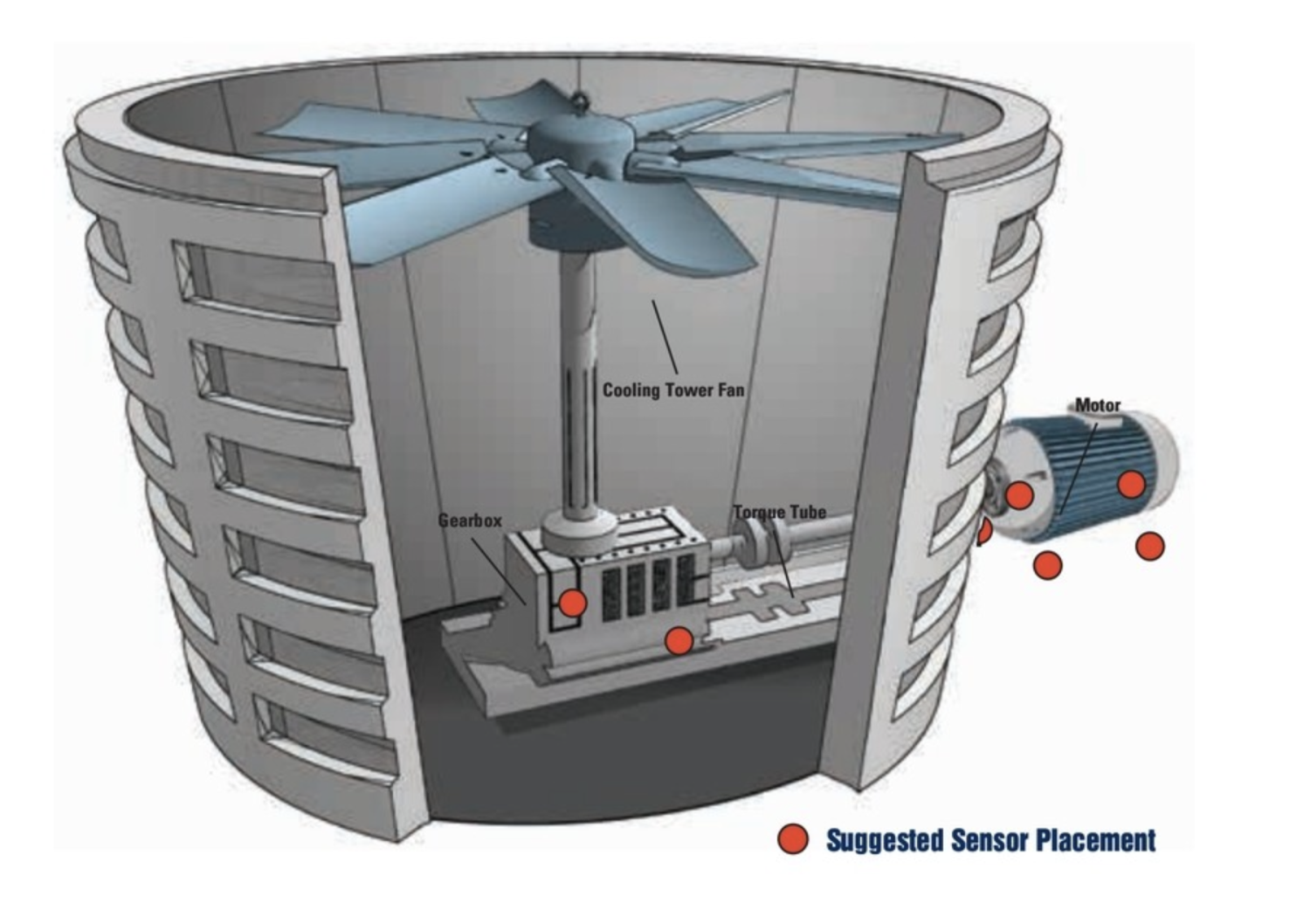

It is generally recommended to install at least one vibration sensor on the motor and gearbox bearings. The installation position of the sensor is shown in the figure above.

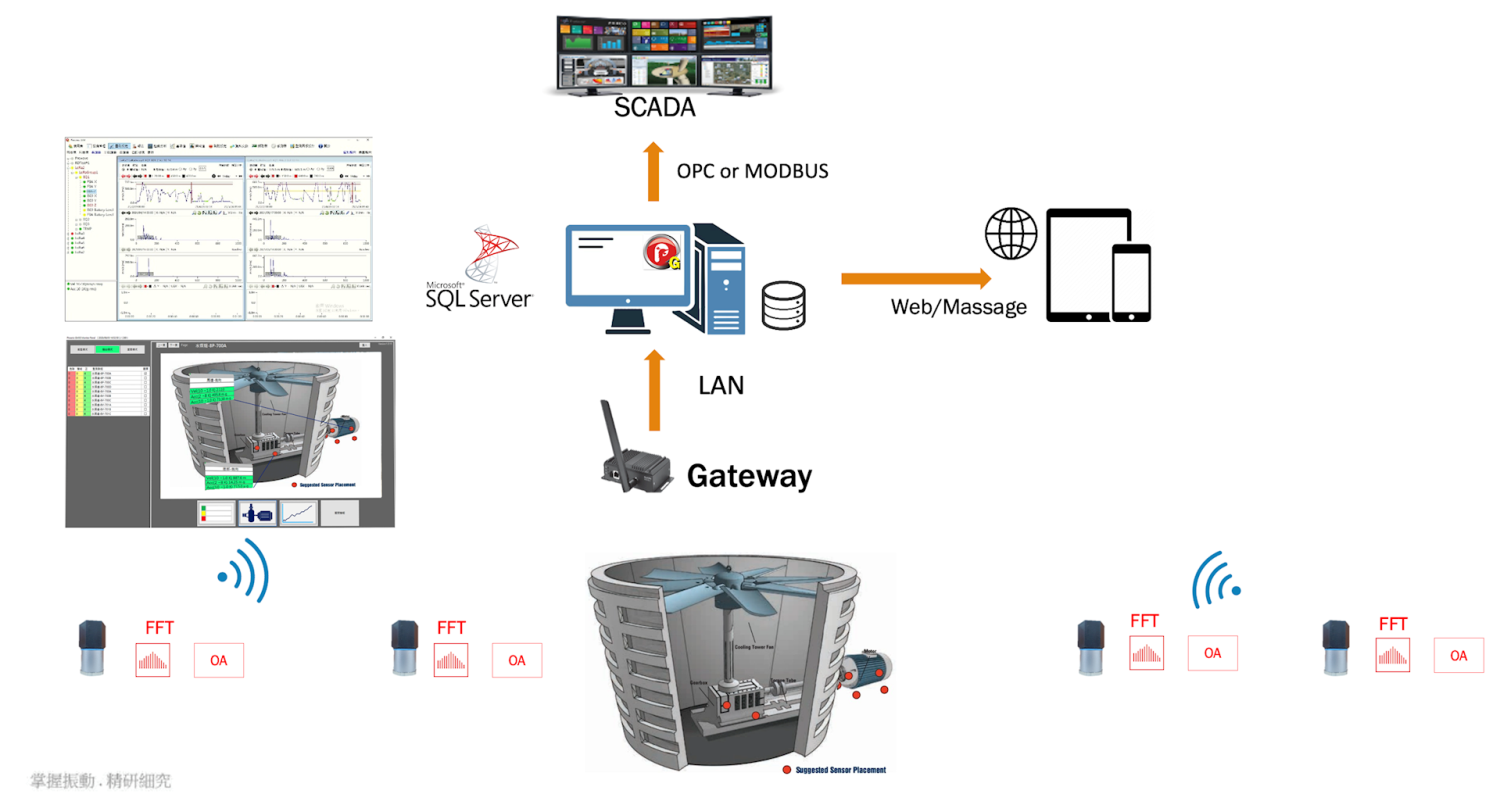

However, the structure and location of cooling towers are often not conducive to regular inspections by personnel, and the cost of pulling physical lines is also high. Puwei Technology proposes a wireless monitoring system solution GM4 Scout & Carrier

The monitoring system GM4 wireless LoRa solution consists of a sensor with 3-axis vibration + temperature, which is transmitted through the LoRa communication protocol with the advantages of long-distance transmission over 400m in actual tests. It has an IP66 waterproof and dustproof rating and can withstand the humid environment of the cooling tower. And unlike ordinary LoRa sensors that can only transmit the total vibration OA, Puwei GM4 system can also provide spectrum information for equipment diagnosis, and has been successfully introduced into the field.

In addition, Puwei Technology has more than 5 vibration analysts who have passed ISO 18436-II certification to assist customers in analyzing and diagnosing equipment problems. Not only provide equipment, but also actually make results.

Learn more about GM LoRa sensor transmission measurement

system structure

|

|