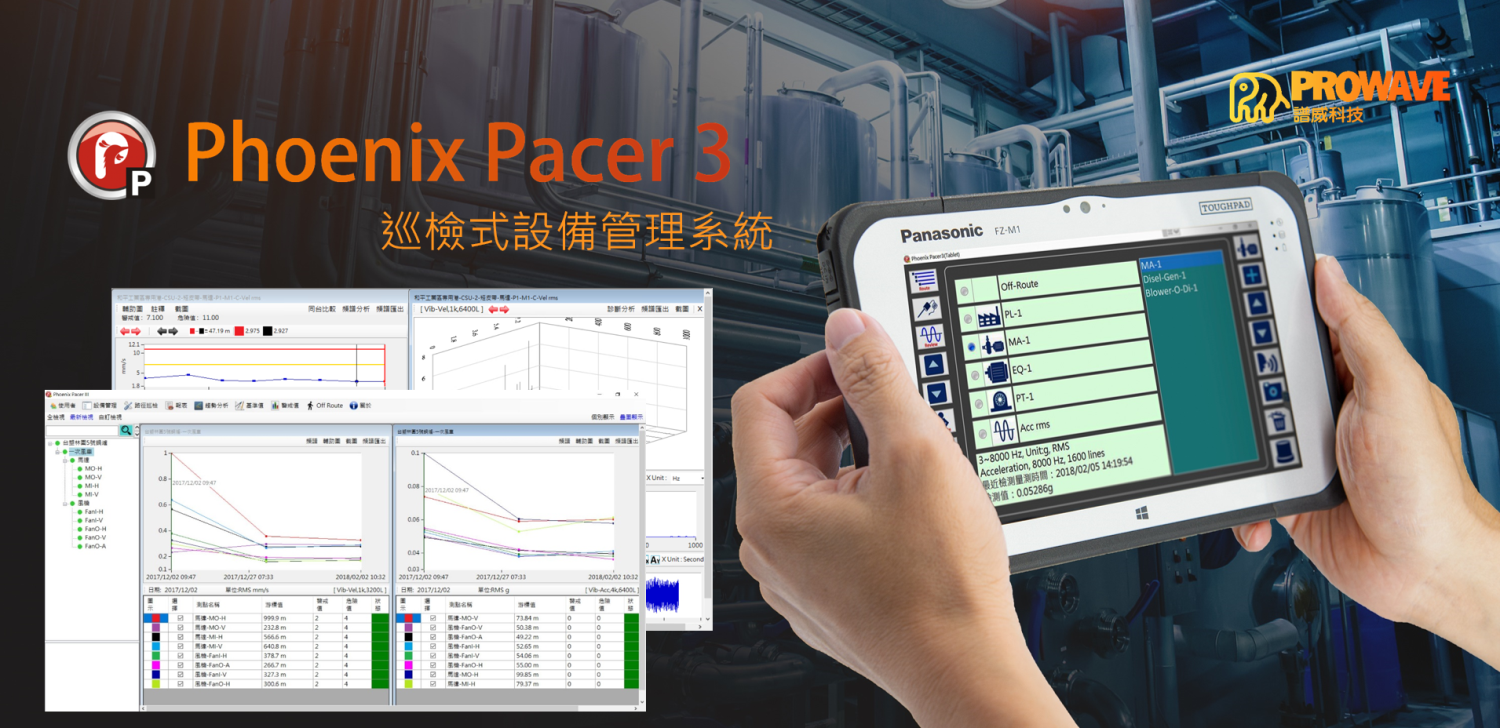

Phoenix Pacer3 equipment inspection management system

There are many rotating equipment in petrochemical plants, among which the number of fans/compressors/mixers is as high as more than 600, and each piece of equipment plays an indispensable role in production management. Nowadays, the concept of predictive maintenance has emerged, replacing it with regular maintenance in the past The goal is to evaluate the most accurate equipment maintenance plan through objective data collection.

However, considering that the initial investment cost would be too high if all 600 devices were monitored online, it was chosen to perform predictive maintenance on the secondary equipment in the form of manual inspection at the initial stage.

Why choose Puwei's Phoenix Pacer3 inspection equipment management system?

|

1. Systematic management of inspection routes It is not easy to manage more than 600 devices. The traditional vibrating meter inspection is easy to repeat the measurement or forget to measure the equipment. Pacer3 can establish the inspection path and provide auxiliary measurement point suggestions, no longer worry about the handover. |

|

|

2. Easy to carry and use on site Pacer 3 has a 7-inch HD touch screen, military-grade protection, a light weight of 0.54 kg, a full Chinese interface, and an anti-glare function so that the information on the screen can still be clearly seen outdoors under the sun. |

|

3. Equipment diagnosis Equipment diagnosis is an important part of predictive maintenance. Pacer3 can not only measure the total amount of vibration, but also record the original data at the same time. With Phoenix Analyzer 3, it makes equipment diagnosis easier. |

|

|

4. Competitive price Pacer3 is a product developed by Pacer through years of experience. In addition to its powerful functions, it also provides a competitive price. |

|