Taiwan's Seismic Reality and the Need for Precision Vibration Monitoring

With continual advancements in electronics and semiconductor manufacturing, even the slightest vibration can affect product yield. Taiwan, located at the boundary between the Philippine Sea Plate and the Eurasian Plate, is particularly prone to frequent seismic activity. In response, semiconductor fabs in Taiwan have widely adopted earthquake and micro-vibration monitoring systems, in addition to active vibration isolation technologies.

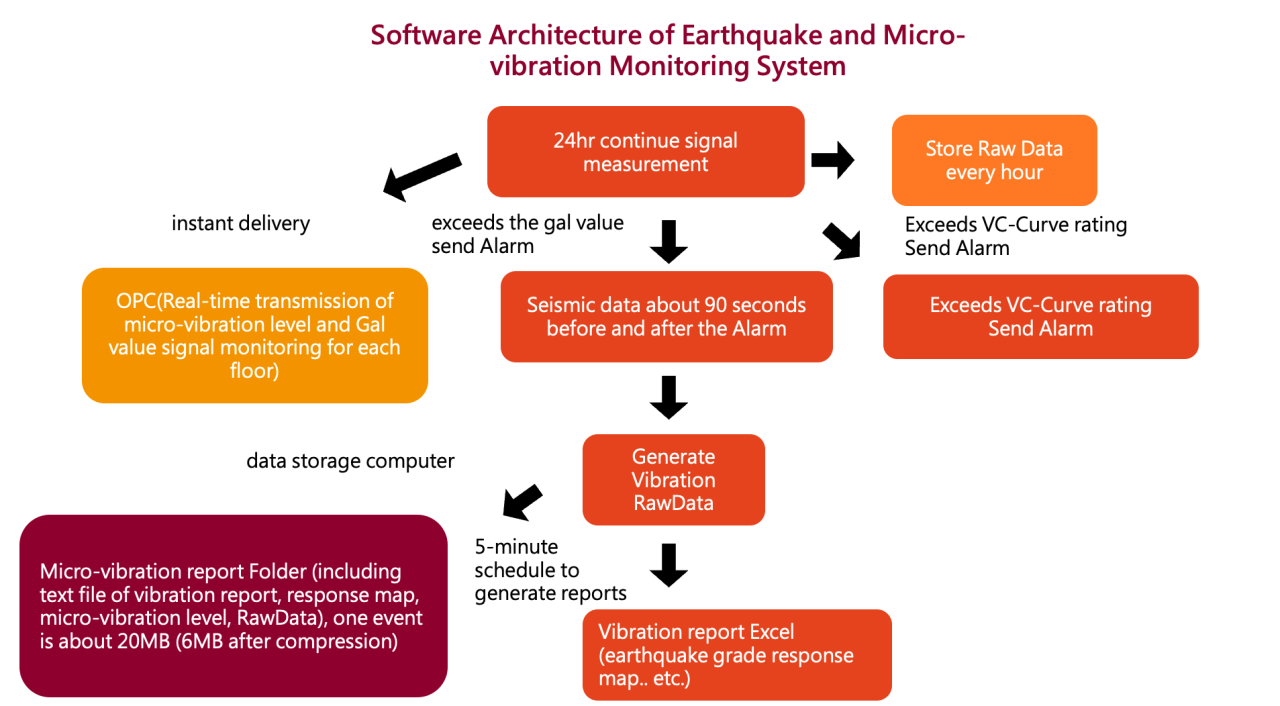

These systems operate 24/7, continuously recording both seismic events and subtle micro-vibrations. The data collected serves as a vital reference for structural engineers working to optimize facility stability and process reliability.

Prowave’s Earthquake and Micro-Vibration Monitoring System is equipped with high-precision sensors capable of detecting extremely small vibrations—down to VC-E level micro-vibrations. Notably, our system successfully captured seismic shockwaves transmitted from the 2011 Tōhoku earthquake in Japan all the way to Taiwan.

Today, Prowave’s system holds over 90% market share in Taiwan’s semiconductor fabs and has become the de facto standard for vibration monitoring in new fab construction by leading semiconductor manufacturers.

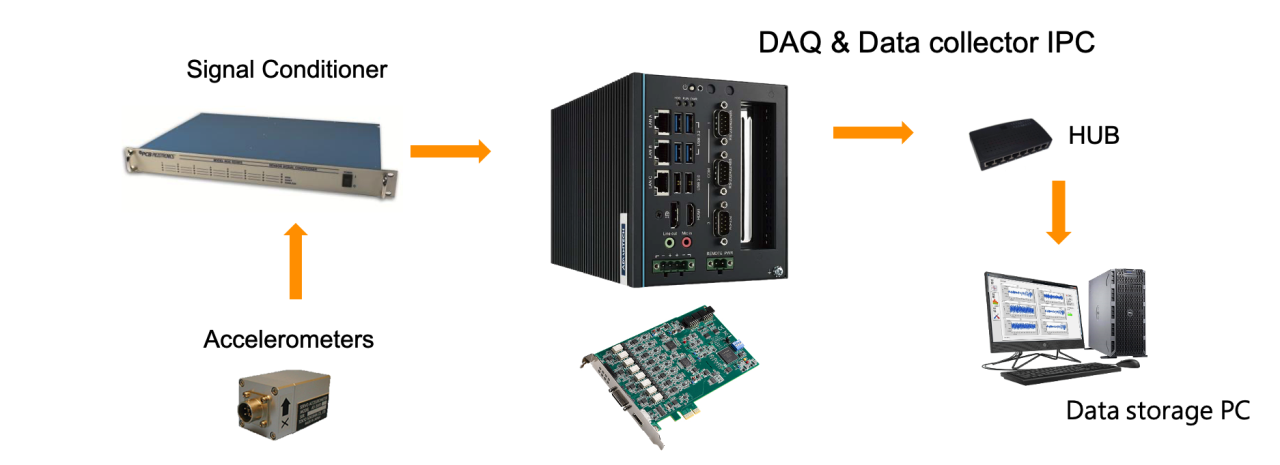

System Structure

|

System measurement configuration: sensor, channel settings, sampling rate, file duration, alert thresholds, data and storage display/configuration, and data transmission settings." |

|

|

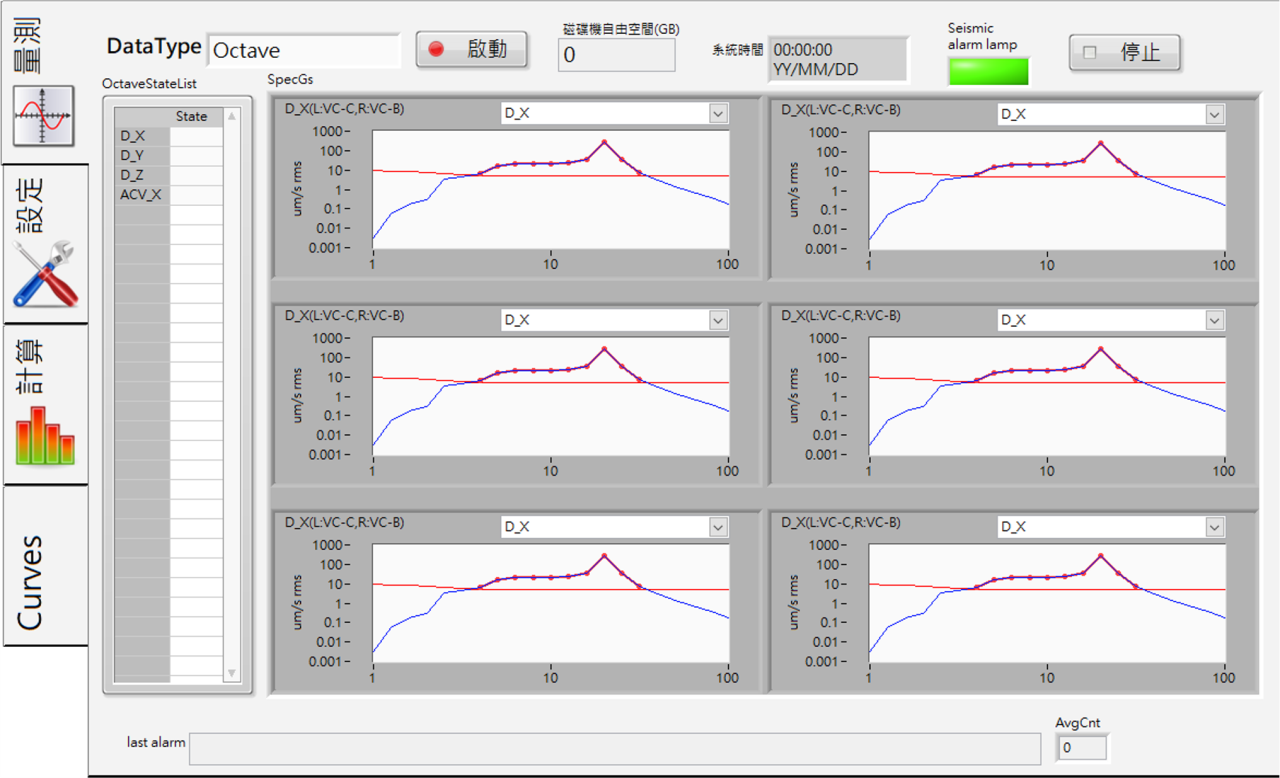

Real-time time-domain/frequency-domain waveform display |

VC-Vcrve DisplayThe VC curve display function enables real-time assessment of whether each measurement point complies with micro-vibration standards, and serves as a primary reference for long-term vibration monitoring |

|

|

Auto Report

|

Trend: Provides raw data loading for trend analysis and data export

|

RAW Viewer: Provides playback of raw measurement data, allows saving selected data segments as new files, and supports export to CSV format

|

.png)

.png)

.png)